Entwicklung, Simulation, Konstruktion & Werkzeugbau.

UNSERE PASSION.

Quality on time.

Globally certified.

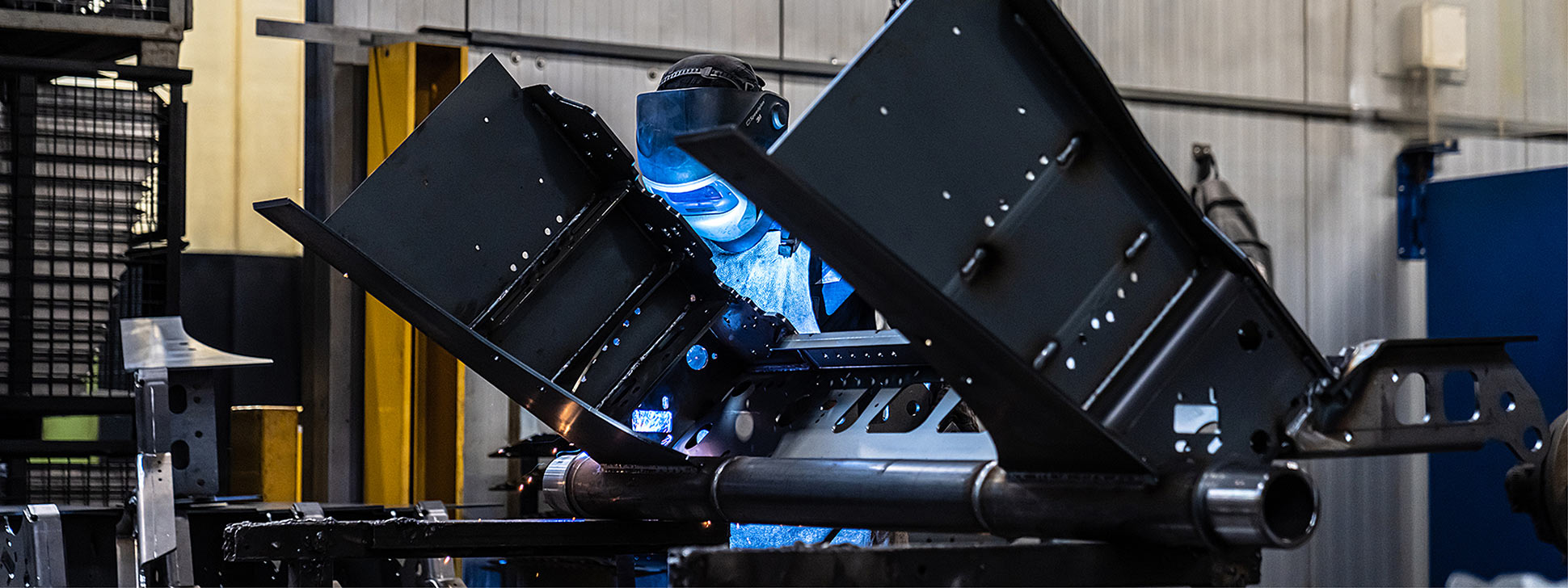

Seit über fünf Jahrzehnten sind wir in der anspruchsvollen Metallverarbeitung aktiv. Wir sind Spezialisten in der Lasertechnik, der Schweißtechnik sowie in der Auslegung und Produktion von Druckluftbehältern. Wir beherrschen die Auslegung der komplexesten Schweißbaugruppen ebenso wie moderne Produktionsprozesse und deren Überwachung.

Torsten Klimmer

Geschäftsführender Gesellschafter

Zwei Firmen unter einem Dach.

Stanz- und Umformteile bis 1.000 t Druckkraft, Blechdicken von 0,8 bis 16 mm, Schweiß- und Lasertechnik, Pulver- und Nasslack-Beschichtungen. Diese Aufzählung verdeutlicht das außergewöhnlich breite Leistungsspektrum unseres Unternehmens.

Qualität.

MATERIALPRÜFUNG.

- Röntgenkontrolle

- 3D-Koordinaten-Messtechnik

- Schliffbildauswertung

- Zugprüfung

ZULASSUNGEN UND ZERTIFIKATE.

- Nationale und internationale Zertifikate

- Weltweite Zulassungen

- Oberflächenqualifikation für die Deutsche Bahn

- Vollständige Übersicht finden Sie hier

QUALITÄTSKONTROLLE.

- Druck- und Dichtigkeitsprüfung

- Röntgenprüfung

- Kontrolle Innen- und Außenbeschichtung

HAUPTANWENDUNGSGEBIETE.

- Schienenfahrzeuge

- Nutzfahrzeugindustrie

- Maschinen- und Anlagenbau

- Komponenten für die Bauindustrie

Fertigungsmöglichkeiten.

Stangenbearbeitung.

Blechbearbeitung.

Schweißen.

Stanzen & Umformen.

Oberflächenbehandlung.

Drahtbiegen.

Logistik.

Unsere Kunden.

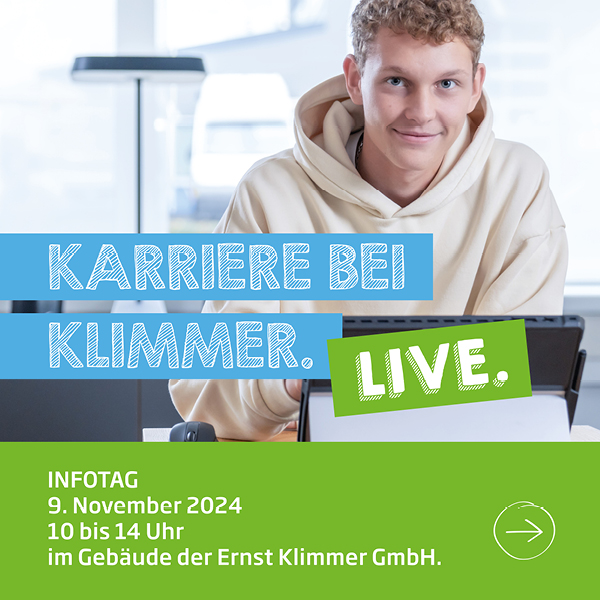

ARBEITEN BEI BSB BWB.

Unser wichtigstes Kapital: Unsere Mitarbeitenden.

Motivierte und zufriedene Mitarbeitende sind die Basis des Unternehmenserfolges. Ebenso ist für Beschäftigte die Arbeit ein wichtiger Teil ihres Lebens. Wir von BSB BWB haben es uns daher zur Aufgabe gemacht, in unser wichtigstes Kapital – die Mitarbeitenden – zu investieren und Arbeitsinhalte und Arbeitsbedingungen kontinuierlich zu optimieren.

Wir fordern und fördern unsere Mitarbeitenden mit regelmäßigen Schulungen und Weiterbildungen, einem hervorragenden Ausbildungsprogramm, einem betriebsinternen Vorschlagswesen und viel Raum für Verantwortung und persönliche Entwicklungsmöglichkeiten.

NEWS.

Eine starke Gruppe.

Die Klimmer Group.

Als einheitliche Dachmarke vereint die Klimmer Group die folgenden vier rechtlich eigenständigen Gesellschaften:

- Ernst Klimmer GmbH

- HMT Häseler Metall Technik GmbH

- BSB Metallverformung GmbH + Co. Stanzwerk

- BWB Behälter-Werk Burgau GmbH + Co. KG

Die Leistungsbereiche fokussieren sich auf hochwertige Produkte in den Bereichen Stanz- & Umformtechnik, Schweißbaugruppen, Druckluftbehälter und technische Sauberkeit.