BSB Metallverformung

GmbH + Co. Stanzwerk.

OUR CORE SKILLS.

BSB has been producing sophisticated punched and formed parts since 1969.

- 10 mm

- Welding and laser technology

- Powder and wet paint coatings

This list illustrates the extraordinarily wide range of services offered by our company. The basis for this is our own toolmaking, a modern machine park and committed employees with well-founded detailed knowledge. At the same time, BSB is the main supplier of individual components for BWB.

“WE ARE THE GROUP’S LEADER IN PUNCHING AND FORMING TECHNOLOGY. WE STRIVE TO DO THE SAME WITH SOPHISTICATED WELDED ASSEMBLIES”

Torsten Klimmer, Managing Director

PUNCHING AND FORMING TECHNOLOGY.

METAL FORMING WITH PASSION.

Whether punching, forming, embossing or hot bending – metal forming is the core of our business. We have been involved in forming technology for more than five decades. We master the development of the most complex tools as well as the latest production processes and their monitoring.

- Automatic forming machines up to 1,000 t compressive force

- Hydraulic presses up to 630 t compressive force

- Embossing presses up to 800 t compressive force

- Coil lines up to 1,000 mm width

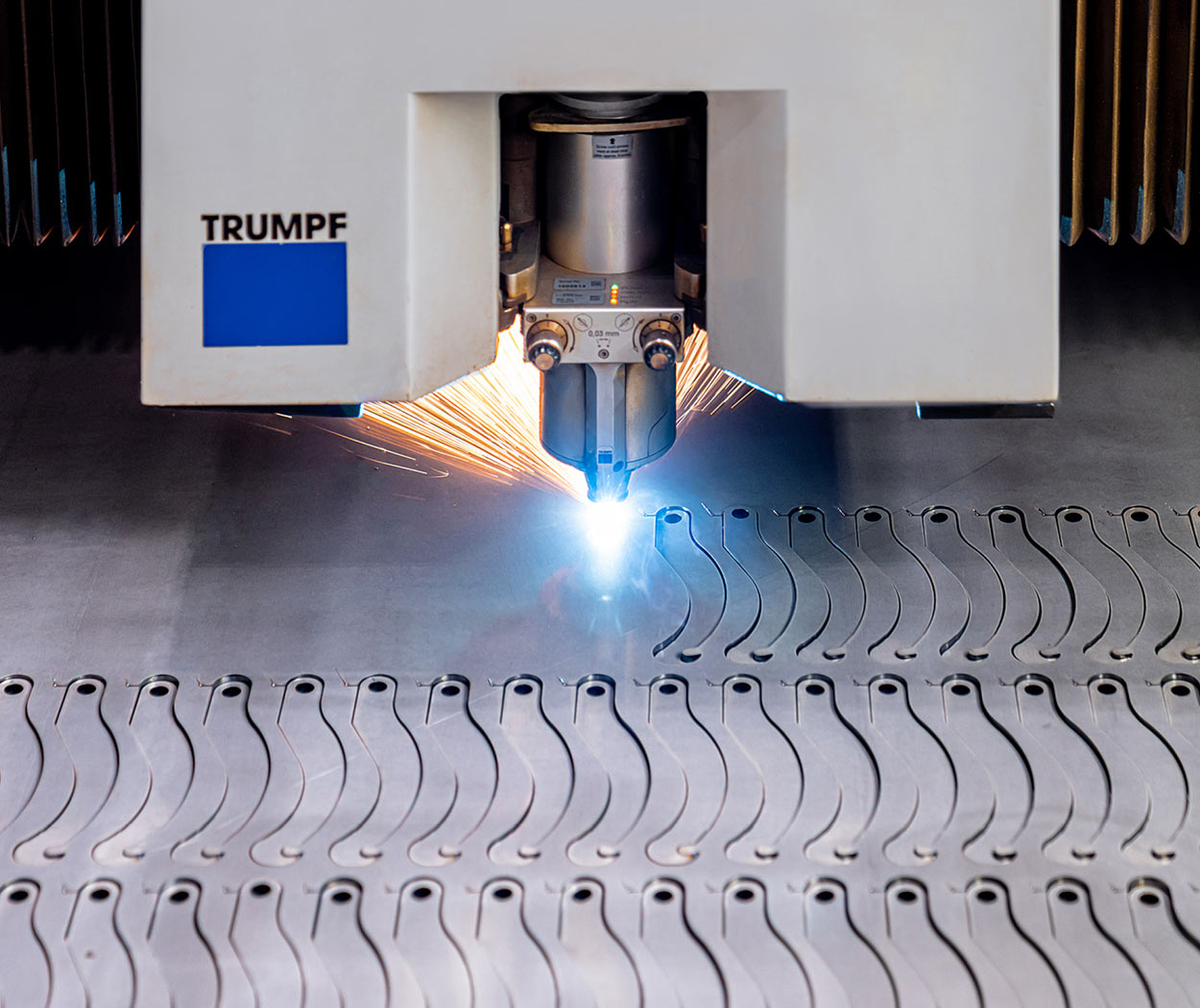

FASCINATION OF SHEET METAL.

SHEET METAL WORKING.

- Laser cutting up to 25 mm

- 3D laser cutting up to 6 mm

- Punching, nibbling up to 8 mm

- Edging, embossing up to 4.20 m bending length

BAR MACHINING AND WIRE BENDING.

- Pipe laser up to 6.4 mm sheet thickness

- Sawing, punching

- Wire thickness up to 8 mm

MACHINING.

- State-of-the-art milling centres up to 3,000 mm table length

- CNC turning centres

- Small series and rush orders in our own production

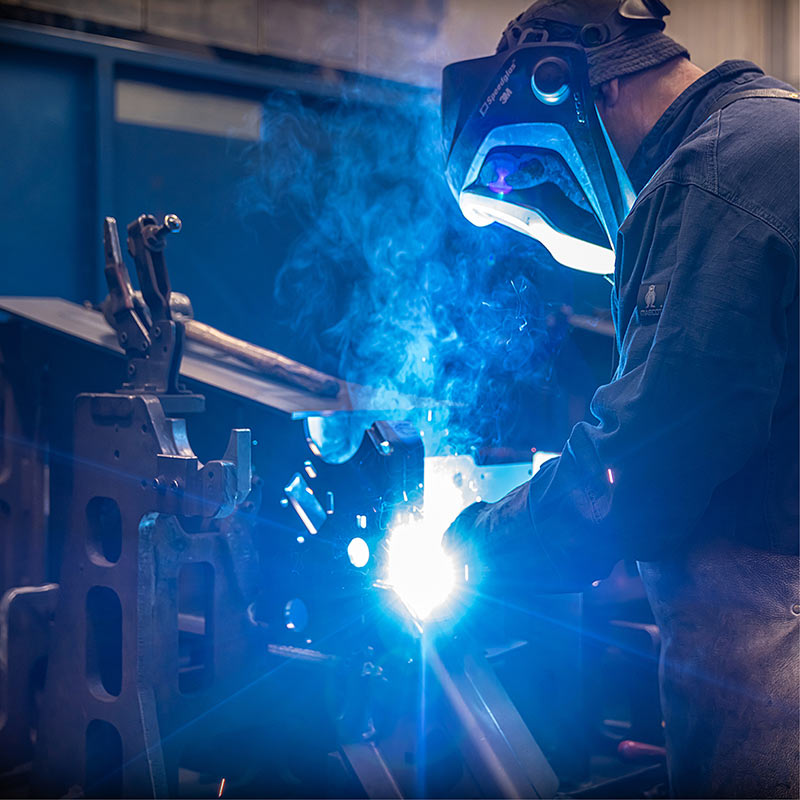

WELDING TECHNOLOGY.

- Laser welding

- MIG, MAG, TIG

- Spot and stud welding

Accreditations:

- DIN EN ISO 3834-2

- EN ISO 1090-1 / -2 / -3

- DIN EN 15085-2 CL1

- More on request

COATING TECHNOLOGY.

INDIVIDUAL SURFACE FINISHING.

We coat and paint with the appropriate process according to your requirements.

- Splash water degreasing, zinc phosphating

- Powder coating

- Wet coating for solvent-based lacquers

- Hot-dip and electrogalvanising, KTL coating, sherardising with external partners

- Other surface coatings on request

TOOLMAKING.

GREATEST KNOW-HOW.

We have been involved in toolmaking for more than five decades. We master the development, simulation, design and manufacture of the most complex punching and forming tools up to 3,600 mm in length. This exceptional know-how directly benefits our customers – through efficient detailed solutions, high economic efficiency and optimum value creation.

INSIGHTS.

INDIVIDUAL AREAS OF APPLICATION.

SHEET METAL BENDING PARTS.

- Wall thicknesses from 0.3 to 8 mm

WELDING CONSTRUCTIONS.

- Laser, spot and stud welding

QUANTITIES.

- From small series to batch sizes

of several thousand pieces

NUMBERS. DATA. FACTS.

IMPORTANT FACTS AT A GLANCE.

Location | Burgau, Germany

Year of foundation | 1969

Employees | 340

Annual turnover | approx. €30 million

Production area | approx. 25,000 m²

Material use | approx. 15,000 t/year

Delivery locations worldwide | 238 in 12 countries